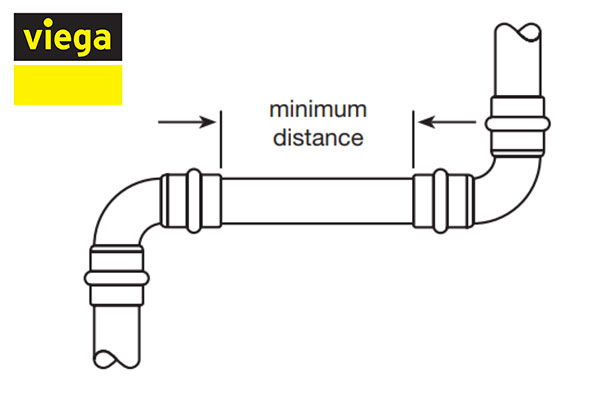

Yes, you can solder a ProPress fitting as long as you remain at least three tube diameters away from the connection to prevent damage to the sealing element. Soldering next to ProPress fittings should be done with caution to ensure the integrity of the connection.

Credit: www.cooneybrothers.com

Soldering Near Propress Fittings

When soldering near Propress fittings, it is important to stay at least three tube diameters away from the connection to avoid damaging the sealing element.

| Can You Solder a Propress Fitting |

| Soldering Near Propress Fittings |

|

| Soldering near Propress fittings requires caution to prevent damage to the sealing element. When soldering next to Propress fittings, it is important to remain at least three tube diameters away from the connection. Prepping the ends for soldering involves cleaning and deburring the pipe ends, ensuring a smooth surface for solder adhesion. Applying flux helps with the solder flow and creates a strong bond. Anchoring the fitting in place ensures that the fitting is stable during the soldering process. Cleaning the joint is crucial to remove any dirt, debris, or oxidation that can affect the soldering quality. Finally, making a solder joint involves heating the joint and applying solder to create a secure connection. |

Credit: blog.supplyhouse.com

Comparing Propress And Solder Fittings

When it comes to comparing Propress and solder fittings, there are a few key factors to consider. The strength and seal of both types of fittings are important for a reliable plumbing system. Propress fittings offer a secure seal without the need for soldering, while solder fittings require a heat source to create a bond.

In terms of cost and time savings, press fittings have the advantage. They require less labor and can be installed quickly and easily with the right press tool. Solder fittings, on the other hand, require more time and skill to ensure a proper solder joint. Additionally, press fittings are suitable for various applications, including residential, commercial, and industrial plumbing systems.

In conclusion, while both Propress and solder fittings have their advantages, press fittings offer strength and a secure seal, along with cost and time savings. They are suitable for a range of applications, making them a versatile choice for plumbing installations.

Credit: www.cooneybrothers.com

Frequently Asked Questions For Can You Solder A Propress Fitting

Can Propress Fittings Be Removed?

Yes, ProPress fittings can be removed. It is recommended to use a trained professional for removal, but if you have the knowledge and specific tools, it is possible to remove and replace a ProPress fitting yourself.

Can You Solder Pro Press Fitting?

Yes, you can solder a ProPress fitting. However, it is important to remain at least three tube diameters away from the connection to prevent damage to the sealing element.

Are Press Fittings As Good As Solder?

Press fittings are as good as solder. They offer a strong fit and seal, while also providing time and labor savings. When soldering next to press fittings, it is important to remain at least three tube diameters away to prevent damage.

How Much Heat Can A Propress Fitting Take?

ProPress fittings can withstand heat when soldering, but it is recommended to remain at least three tube diameters away from the connection to prevent damage to the sealing element.

Conclusion

Soldering a ProPress fitting is possible, but it requires caution and adherence to specific guidelines. Installers must remain at least three tube diameters away from the connection to prevent damage to the sealing element. While press fittings offer a strong fit and seal, soldering can still be an option.

However, it’s essential to weigh the advantages and disadvantages based on individual needs and circumstances. Ultimately, whether to solder a ProPress fitting or use press tools depends on the installer’s preference and specific requirements.