Yes, aluminum can be used as a ground due to its conductivity and ability to dissipate electrical charges effectively. Aluminum is a highly conductive material that is commonly used as a grounding option in various electrical applications.

Its low resistance and high conductivity properties make it an effective material for grounding electrical systems, providing a safe pathway for electrical currents to flow into the earth.

Additionally, aluminum is lightweight, cost-effective, and readily available, making it a practical choice for electrical grounding.

Whether used in residential, commercial, or industrial settings, aluminum’s ability to efficiently dissipate electrical charges helps protect against electrical hazards and ensures the safety and proper functioning of electrical systems.

Understanding Grounding In Electrical Systems

Grounding is an essential aspect of electrical systems to ensure safety and functionality. By providing a reference point for electrical circuits, grounding helps to prevent electrical shocks, fires, and damage to equipment.

Electrical grounding works by creating a direct path for electric current to flow safely into the earth. This is achieved by connecting conductive materials to the ground, such as aluminum, copper, or steel.

These materials are commonly used because of their excellent conductivity and durability, making them ideal for grounding purposes.

The importance of electrical grounding should not be underestimated. It reduces the risk of electrical malfunctions, protects against power surges, and provides a safe path for stray electrical currents.

In summary, proper grounding is crucial for the safe and efficient operation of electrical systems.

Aluminum, along with other conductive materials, can be effectively used as a grounding material to maintain electrical safety and prevent hazards in various applications.

Pros And Cons Of Aluminum As A Grounding Material

Using aluminum for grounding offers several advantages. Firstly, it provides corrosion resistance and has a long lifespan, making it a durable option.

Secondly, its lightweight nature makes it cost-effective and easier to handle during installation.

Additionally, aluminum has high conductivity, allowing for efficient grounding and reducing electrical resistance.

However, there are certain disadvantages associated with using aluminum for grounding. One concern is the risk of oxidation, which can lead to poor connections and weaken the effectiveness of the grounding system.

Aluminum also poses challenges due to thermal expansion and contraction, which can affect its stability over time.

Consequently, increased maintenance and inspections may be required to ensure the proper functioning of the grounding system.

Best Practices For Using Aluminum As A Ground

- Connecting aluminum to other materials

- Using proper connectors and terminations

- Maintenance and inspection tips for aluminum grounding

- Regular cleaning and tightening of connections

- Monitoring the condition of aluminum grounding components

- Signs of potential issues and troubleshooting methods

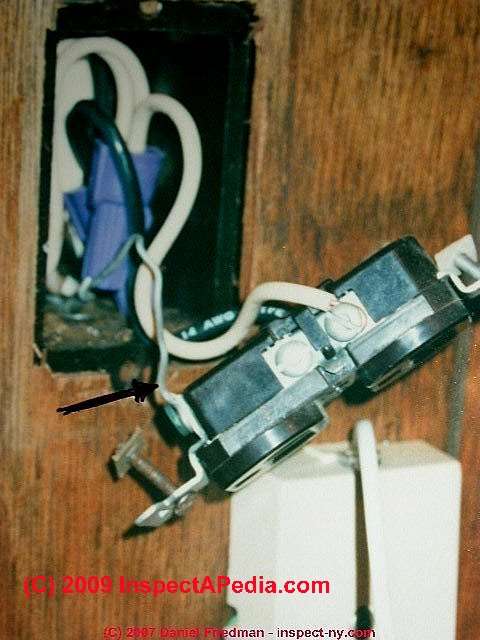

Credit: inspectapedia.com

Frequently Asked Questions

Can Aluminum Be Used As A Ground?

Yes, aluminum can be used as a ground due to its low electrical resistance and availability. It is commonly used in electrical installations as an alternative to copper for grounding purposes. However, proper installation and maintenance are crucial to ensure its effectiveness and long-term reliability.

Conclusion

Overall, aluminum can be effectively used as a ground in various applications. Its conductive properties and cost-effectiveness make it a popular choice among electrical engineers and DIY enthusiasts.

By ensuring proper installation techniques and considering factors such as soil composition and environmental conditions, aluminum can provide a reliable ground connection for electrical systems.

So, next time you’re considering grounding options, don’t overlook the versatility and performance of aluminum.