To add hydraulic fluid to a liftgate, locate the fluid reservoir and pour the hydraulic fluid into it until it reaches the appropriate level. Keep the system free of contaminants by using a clean funnel.

Maintaining the right level of hydraulic fluid in your liftgate is crucial for its smooth operation. Liftgates, which are hydraulic platforms at the back of a truck or van, enable easy handling of heavy cargo. To ensure their reliability and prevent damage to the hydraulic system, it’s vital to check and refill the hydraulic fluid periodically.

A low fluid level can lead to poor lift function and even system failure. This introduction aims to guide you through the simple process of topping off your liftgate’s hydraulic fluid, promoting longevity and peak performance of your equipment. Always refer to the manufacturer’s manual for the specific type of hydraulic fluid recommended for your liftgate model before proceeding.

Credit: liftgateme.com

Introduction To Hydraulic Liftgates

Hydraulic liftgates serve the important role of enabling effortless loading and unloading of cargo from trucks or vans. They operate by utilizing hydraulic fluid to generate the necessary force to lift and lower the platform.

Before proceeding with the addition of hydraulic fluid, one must prioritize safety. Make certain to shut off the engine and ensure that the liftgate is securely supported if it needs to remain in an elevated position. It’s essential to wear protective gear, such as gloves and safety glasses, to prevent injuries from potential hydraulic fluid spills or spray.

Preparation For Hydraulic Fluid Addition

Before beginning the process of adding hydraulic fluid to a liftgate, it is essential to gather the necessary tools and materials. The task requires a set of wrenches, a clean funnel, a rag for wiping, and the appropriate type of hydraulic fluid specified by the liftgate manufacturer. Using the wrong fluid can cause damage to the system, therefore, double-check the liftgate’s manual or identification plate to ensure compatibility.

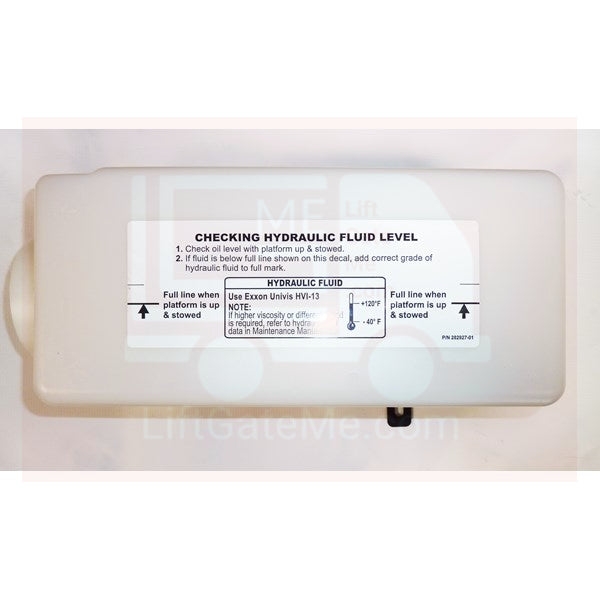

Locating the hydraulic fluid reservoir is a straightforward step that involves inspecting the liftgate for a labeled tank or reservoir. Typically, it can be found near the liftgate’s mechanism; it may be necessary to lift the gate or access panels to reach it. Always inspect for leaks and damages prior to unscrewing the cap of the reservoir to prevent further complications.

- Set of wrenches to open the reservoir

- Clean funnel to pour the fluid without spillage

- Rag for cleaning any excess or spills

- Appropriate hydraulic fluid specified for the liftgate

Step-by-step Process To Add Hydraulic Fluid

Regularly checking the hydraulic fluid levels in your liftgate is crucial for optimal performance. Start by locating the fluid reservoir and wipe it clean with a rag to prevent contamination. This ensures that when you open the reservoir cap, no debris falls into the hydraulic system.

Upon inspection, if the fluid level is below the recommended mark, prepare to add hydraulic fluid. Use a funnel to pour the fluid steadily until it reaches the indicated level. It’s essential not to overfill, as this could lead to excess pressure within the system.

| Steps | Important Notes |

|---|---|

| Clean the area | Prevent debris from entering the system |

| Check fluid level | Ensure it’s below maximum mark |

| Add fluid slowly | Avoid overfilling the reservoir |

| Ensure proper circulation | Run the liftgate to distribute the fluid |

After adding the necessary amount of fluid, activate the liftgate several times to allow the new fluid to circulate properly. This step is vital for maintaining the hydraulic system’s integrity and ensuring the liftgate functions smoothly.

Credit: www.tommygate.com

Troubleshooting Common Issues

Dealing with Hydraulic Fluid Overfill often involves carefully siphoning out the excess fluid to avoid pressure build-up and potential damage to the liftgate system. Ensure the hydraulic reservoir is cool and the vehicle is on level ground before attempting to remove any fluid to prevent spillage and potential injuries.

For Addressing Leaks and Preventing Contamination, it’s vital to conduct regular checks for any signs of wear and tear. Spotting hydraulic fluid on the ground beneath the liftgate or noticeable drops in fluid levels can signify a leak. Replace worn seals and hoses promptly, and always use clean funnels and containers when topping up the hydraulic fluid. This prevents the introduction of debris that could impair the system’s function.

Should one encounter a scenario where the Liftgate Still Doesn’t Operate Smoothly after adding the correct level of hydraulic fluid and ensuring there are no leaks, it might be necessary to inspect the liftgate’s mechanism for potential obstructions or misalignments. A professional technician should calibrate the system for optimal performance or troubleshoot for more complex issues like pump or valve malfunctions.

Maintenance Tips For Hydraulic Liftgate Systems

Maintaining a hydraulic liftgate necessitates consistent inspection and fluid level checks to ensure its smooth operation. It’s vital to assess the liftgate’s hydraulic fluid levels routinely, typically situated near the base of the liftgate itself. A transparent reservoir or a dipstick often provides an immediate visual indication of the fluid level. Should levels fall below the recommended line, topping off with the appropriate hydraulic fluid is essential.

Choosing the correct hydraulic fluid is integral to liftgate performance and longevity. Fluid specifications can usually be found in the manufacturer’s manual, and using an incompatible type could lead to damage or reduced functionality. Only fluids designed for hydraulic systems should be used.

Lastly, scheduling regular maintenance with a professional can prevent unexpected failures and costly repairs. Qualified technicians can detect issues early on and provide the necessary services, from fluid changes to part replacements, to keep the liftgate in peak condition.

Credit: www.amazon.com

Frequently Asked Questions Of How To Add Hydraulic Fluid To A Liftgate

What Kind Of Hydraulic Fluid Goes In A Liftgate?

The appropriate hydraulic fluid for a liftgate is typically an ISO 32 or equivalent anti-wear hydraulic oil. Always consult your liftgate’s manual for specific recommendations.

How Do You Add Fluid To A Hydraulic Jack?

To add fluid to a hydraulic jack:1. Ensure the jack is fully lowered. 2. Locate the filler plug. 3. Remove the plug. 4. Fill with hydraulic fluid to the recommended level. 5. Reinstall the plug securely.

How Do You Put Oil In A Hydraulic Lift?

Ensure the hydraulic lift is off and fully lowered. Locate the hydraulic fluid reservoir. Unscrew the filler cap. Pour the appropriate hydraulic oil into the reservoir, taking care not to overfill. Replace the filler cap securely.

How Do You Get Hydraulic Fluid Up?

To remove hydraulic fluid, use a siphon pump or absorbent material. For spills, apply an absorbent, then sweep and discard properly. Always wear protective gloves and follow environmental disposal regulations.

Conclusion

Maintaining your liftgate with the correct hydraulic fluid ensures longevity and safety. By following the steps outlined, you can effortlessly replenish the fluid and improve your liftgate’s performance. Remember, regular checks prevent costly repairs. Keep this guide handy for your next top-up and drive with confidence.